In today’s highly competitive manufacturing landscape, quality control is more crucial than ever. Flawless product inspection is the backbone of delivering high-quality goods, reducing waste, and maintaining brand reputation. At the forefront of this revolution is machine vision—a transformative technology that automates and perfects the inspection process.

In this article, Sciotexe explores how machine vision drives flawless product inspection, improving accuracy, speed, and reliability in manufacturing industries worldwide.

What is Machine Vision?

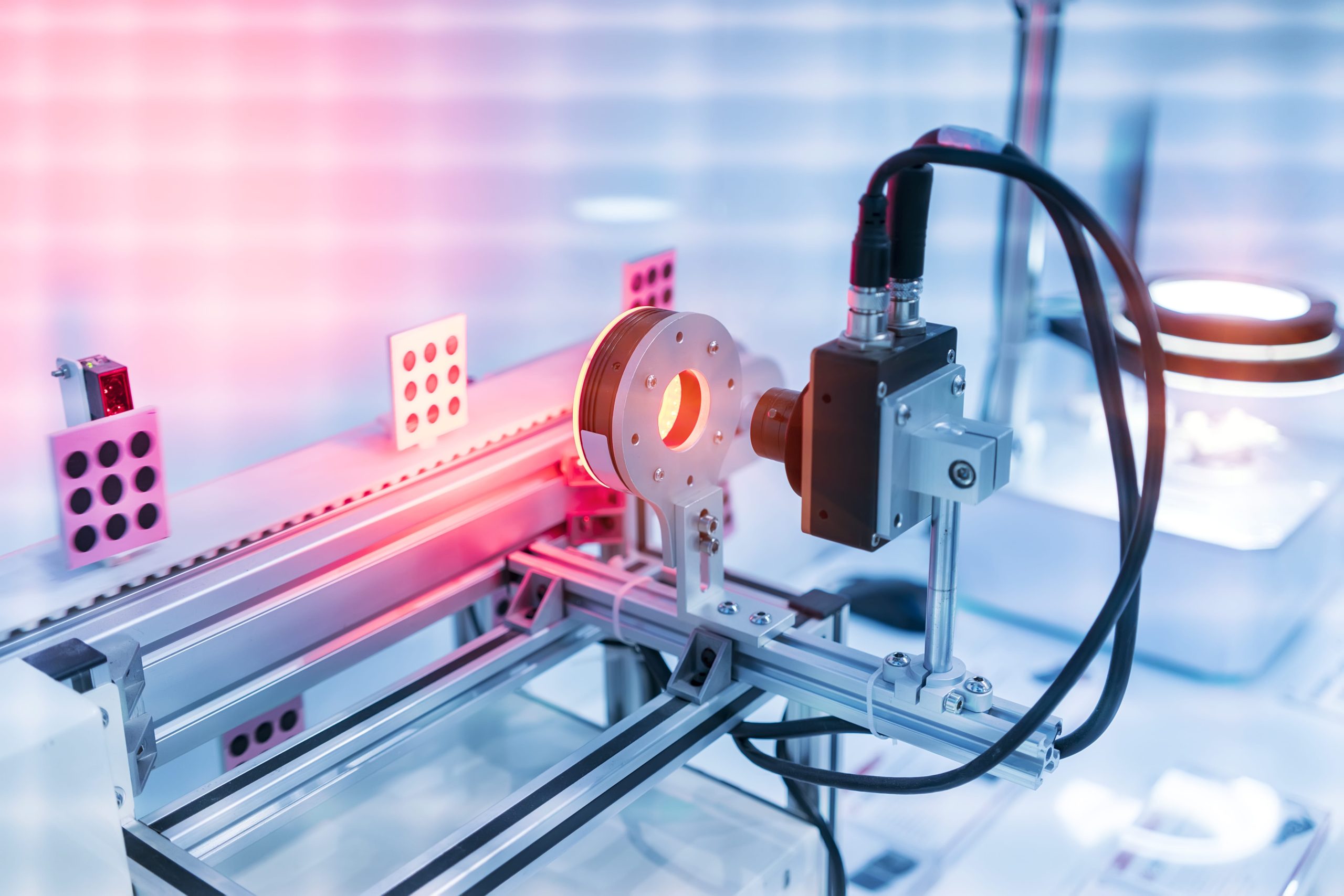

Machine vision refers to the technology and methods used to provide imaging-based automatic inspection and analysis for applications such as automatic inspection, process control, and robot guidance. It combines cameras, lighting, sensors, and software algorithms to “see” and interpret visual data similarly to the human eye but with greater speed, consistency, and precision.

Unlike traditional manual inspection methods, machine vision systems can rapidly analyze products on the production line without fatigue or human error, ensuring every item meets stringent quality standards.

The Role of Machine Vision in Product Inspection

Product inspection is a critical step in the manufacturing process that ensures only products that meet quality standards reach the consumer. Here’s how machine vision elevates this process:

1. Superior Accuracy and Consistency

Human inspectors, despite their expertise, can suffer from fatigue and inconsistency. Machine vision systems maintain a high level of accuracy throughout the inspection cycle, eliminating variations caused by human factors. This leads to fewer defective products slipping through and reduces costly recalls.

2. Real-Time Quality Control

With integrated cameras and sensors, machine vision can inspect products at production line speeds, often capturing thousands of images per second. This real-time inspection capability means defects are detected immediately, allowing for rapid intervention and minimal disruption.

3. Detection of Complex Defects

Machine vision is capable of detecting subtle defects that are often invisible to the naked eye, including surface imperfections, color variations, dimensional inaccuracies, and assembly errors. Advanced algorithms can analyze patterns and textures, enabling flawless detection of complex flaws.

4. Scalability and Flexibility

Whether manufacturing small batches or large-scale production, machine vision systems can be tailored and scaled to fit specific industry needs—from electronics and automotive parts to pharmaceuticals and food products.

Key Components of Machine Vision Systems for Inspection

A typical machine vision system consists of:

- Image Acquisition Devices: Cameras (2D or 3D) capture high-resolution images of products.

- Lighting: Proper illumination is essential for highlighting defects and ensuring clear images.

- Image Processing Software: Advanced algorithms analyze images for deviations and defects.

- Output Devices: Systems that provide actionable feedback or trigger rejection mechanisms on the line.

Benefits of Machine Vision for Flawless Product Inspection

Implementing machine vision for product inspection offers a multitude of benefits that directly impact manufacturing efficiency and product quality:

Enhanced Product Quality

Consistent inspection standards ensure every product meets quality benchmarks, improving customer satisfaction and brand loyalty.

Reduced Operational Costs

By minimizing human labor costs and reducing waste caused by defective products, machine vision contributes to substantial cost savings.

Increased Production Speed

Automation accelerates inspection without compromising accuracy, allowing manufacturers to meet high demand without quality trade-offs.

Data-Driven Insights

The digital nature of machine vision systems provides manufacturers with valuable data on defect trends, enabling continuous process improvement.

Applications of Machine Vision in Various Industries

The versatility of machine vision technology allows it to be used across numerous industries, each with unique inspection requirements:

- Electronics: Inspecting circuit boards for soldering defects and component placement.

- Automotive: Checking body panels, welds, and paint jobs for imperfections.

- Pharmaceuticals: Ensuring packaging integrity, label accuracy, and product counting.

- Food and Beverage: Detecting contaminants, verifying fill levels, and inspecting packaging seals.

- Textiles: Identifying fabric defects like holes, stains, or weaving inconsistencies.

Challenges and Considerations When Implementing Machine Vision

While machine vision brings many advantages, manufacturers should be aware of challenges such as initial setup costs, system calibration, and integration complexity. Properly defining inspection criteria and working with experienced vendors like Sciotexe can streamline adoption and maximize ROI.

Future Trends in Machine Vision for Product Inspection

Machine vision continues to evolve rapidly with advances in artificial intelligence (AI), deep learning, and edge computing. These technologies promise even greater inspection accuracy, predictive quality control, and autonomous decision-making on the factory floor.

Conclusion

The integration of machine vision into product inspection processes is transforming manufacturing by ensuring flawless quality, boosting efficiency, and reducing costs. For manufacturers seeking to stay competitive and deliver impeccable products, machine vision is no longer optional—it’s essential.

At Sciotexe, we understand the power of machine vision technology and its role in driving excellence in quality control. Embrace machine vision today to elevate your production standards and gain a competitive edge in your industry. Our website is your ultimate source of valuable information.

Frequently Asked Questions (FAQs)

Q1: What is the primary advantage of machine vision over manual inspection?

A1: Machine vision provides superior accuracy, speed, and consistency while eliminating human error and fatigue, resulting in higher quality product inspection.

Q2: Can machine vision detect defects invisible to the human eye?

A2: Yes, advanced machine vision systems use high-resolution cameras and sophisticated algorithms to detect subtle defects such as micro-cracks, color variations, and dimensional inaccuracies.

Q3: Is machine vision suitable for all types of manufacturing industries?

A3: Absolutely. Machine vision is highly versatile and can be adapted for diverse industries including electronics, automotive, pharmaceuticals, food and beverage, and textiles.